diesel pellet mill

It is well-known that the diesel pellet mill is the best choice for people who want to cut down cost on the energy consumption. This type of machine stands out the facts that it can be put to use in many regions especially in the distant areas where power is deficient.

Generally, diesel engine is applied to small flat die pellet machines and its application is very extensive. With more and more people is hunger for using pellet mill to create heat to their family, so the needs of pellet mill with diesel engine is also increasing nowadays.

Advantages of Diesel Pellet Mill

- CE&ISO certificate;

- Long service life with alloy steel principle shaft box and upper box;

- Pellets are of uniform, hard and smooth;

- Low noise, high endurance, low temperature, changing with alloy steel carbon-quenched multiple geared system.

- Simple operation, low energy consumption and less manpower;

ZLSP R-type Diesel Pellet Mill

.jpg)

.jpg)

.jpg)

ZLSP R-type Diesel Pellet Mill Specification

| Model | Power | Capacity | Weight(NW/GW) | Packing Size |

|---|---|---|---|---|

| ZLSP200A R-type | 15 HP | 80-120kg/h | 320/350kg | 1460*950*1100mm |

| 170-270lbs/h | 705/772lbs | 58*37*55inch | ||

| ZLSP300A R-type | 36 HP | 250-350kg/h | 850/890kg | 1100*700*2480mm |

| 550-770lbs/h | 1874/1962lbs | 43*28*98 inch | ||

| ZLSP400A R-type | 55 HP | 350-450 kg/h | 1010/1050kg | 1300*800*2600mm |

| 770-990 lbs/h | 2227/2315lbs | 51*31*102 inch |

Rotating Die ZLSP D-type Diesel Pellet Mill

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Technical data of ZLSP D-type pellet mill with diesel motor

| Model | Power | Capacity | Weight(NW/GW) | Packing Size |

|---|---|---|---|---|

| ZLSP120A | 8 HP | 40-80kg/h | 120/140kg | 900x500x730mm |

| 90-180lbs/h | 265/310lbs | 35*20*29inch | ||

| ZLSP150A | 8 HP | 50-100kg/h | 180/220 kg | 1000*500*750mm |

| 110-220lbs/h | 400/490 lbs | 39*20*30inch | ||

| ZLSP200A | 15 HP | 80-120 kg/h | 210/240 kg | 1460*750*900mm |

| 180-265lbs/h | 460/530 lbs | 58*30*35inch | ||

| ZLSP230A | 22 HP | 120-200kg/h | 280/310 kg | 1560*850*1000mm |

| 245-440lbs/h | 620/680 lbs | 61*33*39inch | ||

| ZLSP260A | 35 HP | 160-250kg/h | 330/360 kg | 1200*500*1070mm |

| 350-550 lbs/h | 730/790 lbs | 47*22*41inch | ||

| ZLSP300A | 55 HP | 250-400kg/h | 410/450 kg | 1220*600*1000mm |

| 550-880 lbs/h | 900/990 lbs | 48*23*39inch |

This kind of pellet mill with diesel motor is also able to press a wide variety of ram material into high quality pellets. For example, it can do with the common biomass material which covers switch grass, rice husk, corn stover, wheat straw etc. But one important factor you should not ignore is the moisture content of raw material, which should be kept at an amount of about 15%.

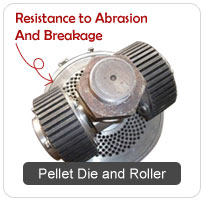

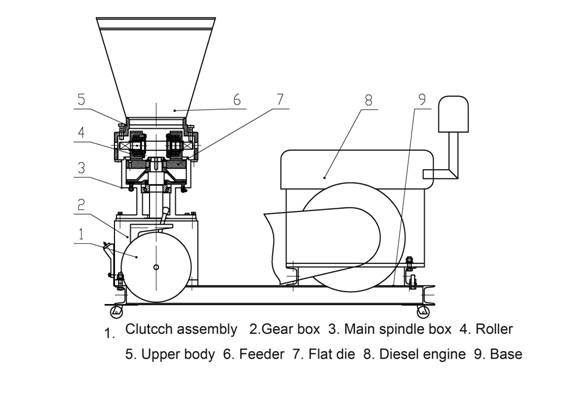

This kind of pellet mill with diesel motor is also able to press a wide variety of ram material into high quality pellets. For example, it can do with the common biomass material which covers switch grass, rice husk, corn stover, wheat straw etc. But one important factor you should not ignore is the moisture content of raw material, which should be kept at an amount of about 15%.Structure of Diesel Pellet Mill

Because of its mobility, diesel pellet mill can be stated to be one of machine which is an easy matter to repair and operate. What’s more, it seldom causes danger to the children with no cabling. With a workhorse of 7 to 8HP, a diesel engine can accept a large production work on a daily basis. Now a number of people realize that the pellets and biomass fuel are renewable and green energy, people are keen on attaining a substantial amount relevant information or news of diesel pellet machine from internet or magazines.

We believe that this is a kind of strong and safe machine to your daily life. But make sure not to excess its greatest capacity, consumers should always operate machine according to the right methods or handbook from the manufactures or agents.

From now on, GEMCO will conduct its business under the ...

The 117th China Import and Export Fair() will be held d...

MPL300 small mobile pelletizing system is a compact pell...

How are wood pellet made? Here is professional wood pell...

Homemade pellet mill is now a hot sale machine for the c...

The D-Type mini pellet mills are powered with an electri...